- Forward osmosis is not dead – interview with leading water consultant Walid Khoury - August 30, 2020

- Listing of major commercial & academic FO players on ForwardOsmosisTech - April 12, 2020

- 0.26MGD FO-SWRO Hybrid for seawater desalination achieves 25% energy reduction compared to MF/SWRO - December 14, 2019

General classification of forward osmosis systems and their applications

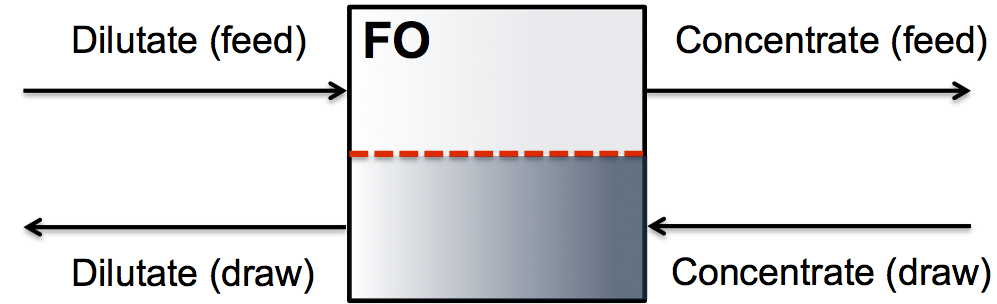

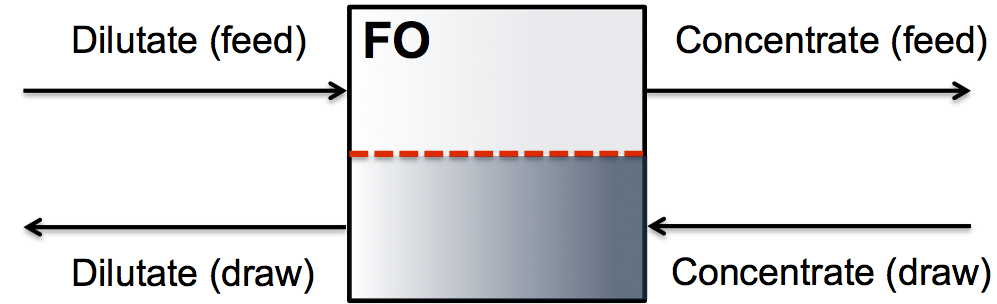

FO systems can be divided into two broad categories, namely stand-alone FO systems and hybrid FO systems. Here, stand-alone FO systems are described in more details.

In a stand-alone FO system, as illustrated schematically above, the outputs are a concentrated feed solution and a diluted draw solution. As such, the stand-alone FO system can be viewed as an energy-efficient water extractor; extracting water from the low concentration feed side to the high concentration draw side.

Water extractor for industrial process optimization

A typical example of a stand-alone FO system application is where the feed and draw solutions represent waste water streams, which become cheaper to dispose of once they are concentrated and diluted respectively.

Specifically, researchers have proposed to use the brine waste from the process of desalinating seawater as the draw solution to concentrate industrial or municipal waste water. Brine waste, with its higher density compared to seawater, drops to the ocean floor in large plumes upon discharge. If these plumes reach the ocean floor without being sufficiently diluted, the marine life on the seabed is damaged. Consequently, brine waste must be discharged through long pipelines to a distance from the shore where the ocean depth facilitates sufficient dilution of the brine plumes. Construction of said pipelines combined with the OPEX costs of pumping the brine constitute a significant part of the total costs of desalination.

Hence, the economical benefits of using a stand-alone FO system to dilute brine waste and at the same time concentrate industrial or municipal waste water, include:

- The diluted brine can be safely discharged closer to the shore, saving costs of pipeline construction & operation

- The industrial or municipal waste water has been reduced in volume, saving costs of transporting the waste water to subsequent treatment facilities

Osmotic power generators

In another application of a stand-alone FO system application, the feed stream is a low TDS (total dissolved solids) fresh water source (e.g. river water, reject from a water reclamation plant, surface water etc.) and the draw stream is a high TDS water source (e.g. seawater, brine reject from desalination etc.). During operation, the water extracted from the low concentration feed to the high concentration draw is used to build up hydraulic pressure on the draw side. The pressure generated in this process can subsequently be harnessed for energy production. The process of generating energy from osmotic pressure differences is referred to as pressure retarded osmosis (or PRO in short).

The economical benefits of PRO, in the case where the draw stream is brine reject from desalination, include:

- Energy production

- The diluted brine can be safely discharged closer to the shore, saving costs of pipeline construction & operation in desalination plants

The global energy potential of PRO is estimated to 2000 TWH/year compared to a global energy production of all renewable sources of 10000 TWH/year (Achilli et. al., 2009). At an estimated average global energy price of 0,2 USD/kWh (Wikipedia and www.energy.eu), the energy potential from PRO is worth a whopping 400 billion USD/year.

Statkraft, a Norwegian state owned Electricity Company with Europe’s largest production of renewable energy, and SINTEF, Scandinavia’s largest independent research organization, were until recently[1] at the forefront of PRO development. Scientists at Statkraft and SINTEF have estimated that PRO membranes are commercially profitable if they can deliver a power density of at least 5 W/m2 or more (Achilli et. al, 2009). With a power density of 5 W/m2 and energy prices of 0,2 USD/kWh, a PRO system will generate yearly revenue of 8,8 USD/m2. According to Loeb et. al. (Loeb et. al., 1976), the yearly cost of energy production[2] – excluding membrane costs – in PRO systems amounts to 2,8 USD/m2. Thus the net yearly revenue is 6 USD/m2, and with an expected membrane lifetime of 5 years, the lifetime gross profit generated per m2 of membrane adds up to 30 USD/m2. This leaves plenty of room for a potential PRO module sales price up to 20 USD/m2 (leaving a net lifetime profit of 10 USD/m2), which is double the current sales price of standard RO modules for desalination. The potential PRO module sales price is expected to increase in time as energy prices rise (potentially through subsidizing) and membrane performance increases.

With a power density of 5 W/m2, a total installed membrane area of 46 Gm2 (46000km2 or roughly the size of Denmark) is needed to capture the full PRO energy potential of 2000 TWH/year. At a 20 USD/m2 sales price, the total global market potential for PRO membranes – excluding overall osmotic generator system costs – then comes in at 920 billion USD.

[1] December 20th 2013, Statkraft announced that they were puling the plug on their PRO work. Most likely this decision was a direct result of a lack of commercially available low-cost high-performance PRO membranes

[2] Production costs include fixed costs of production, costs of pretreatment facilities, hydro turbine and generator costs, labour costs, and diversion dam costs.

Interesting topic

Hello

I am looking for a low energy water extraction from feed solution (Inorganic salt) using concentrated brine (sodium chloride). Can anyone have any recommendations on where i can get such a system… or anyone can help me whether it is feasible for our given system…we want to scale up the process pretty quickly… only practical solution is needed.

Appreciate your help..

Hi Krishna,

Thanks for reaching out via ForwardOsmosisTechPortal. Could you possibly share some more details of the system you are looking for (i.e. desired system capacity, concentration of feed and draw streams, desired water recovery from feed stream, any specific forward/reverse rejection requirements, any footprint requirements of the system, etc)?

Once we have the details, we can forward your request on ForwardOsmosisTech’s LinkedIn group as well.

Cheers

Mark

Need aa better brine recovery FO system of 50cubic meter per day for a solution of sodium chloride and sdium sulphate. PLEASE ADVICE WHICH TYPE OF FORWARD OSMOSIS IS REQUIRED FOR SEPARATING MAINLY BRINE AND HOW IT WILL BE DISPOSED.