- Forward osmosis is not dead – interview with leading water consultant Walid Khoury - August 30, 2020

- Listing of major commercial & academic FO players on ForwardOsmosisTech - April 12, 2020

- 0.26MGD FO-SWRO Hybrid for seawater desalination achieves 25% energy reduction compared to MF/SWRO - December 14, 2019

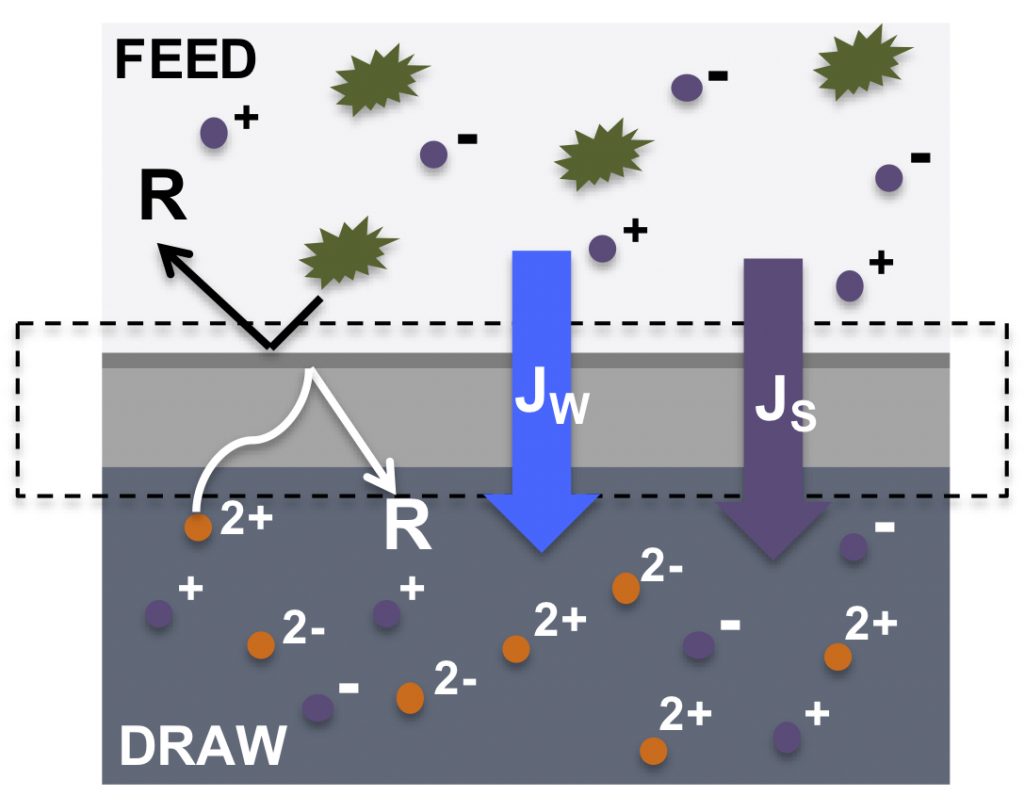

Could an FO membrane be designed to extract both water and selected solutes from wastewater streams?

Conventional forward osmosis membranes are designed to extract water from feed streams while rejecting virtually all other compounds.

What if, instead, we were to design a more open Nanofiltration (NF)-type FO membrane with selective rejection properties? As an example, it should be possible to tailor the FO rejection layer to yield high rejection for divalent salts (e.g. MgSO4) and low rejection for monovalent salts (e.g. NaCl).

What we end up with, is an FO membrane capable of simultaneously desalting and de-watering wastewater streams.

In addition, the NF-type FO membrane would likely enjoy a higher water flux and less concentration polarization.

Everything else equal, the added value from the recovered salt should improve overall system ROI. But how much improvement can potentially be gained?

The following is a desktop study based on the work by Vishnu and co-workers (“Assessment of fieldscale zero liquid discharge treatment systems for recovery of water and salt from textile effluents.” Journal of Cleaner Production 16.10 (2008): 1081-1089.).

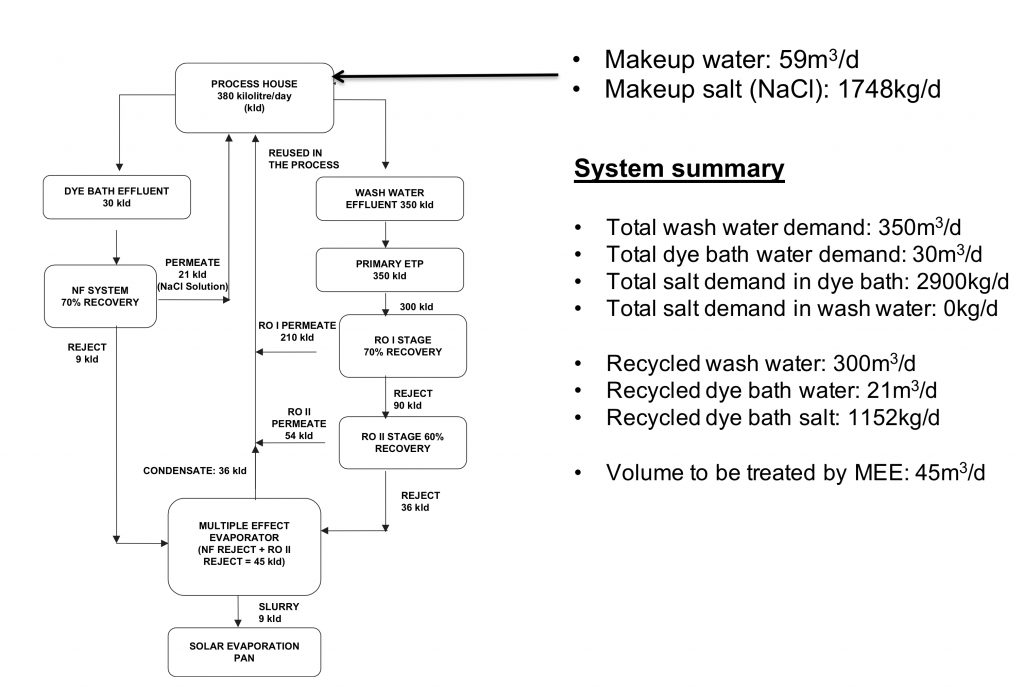

Comparison: conventional NF/RO/MEE zero liquid discharge system for treatment of wastewater from textile dyeing

Conventional zero liquid discharge (ZLD) systems typically deploy membrane based technologies in combination with evaporators. The summary below is based Vishnu et. al. 2008 and shows an example of a conventional ZLD system applied for treatment of wastewater from textile dyeing.

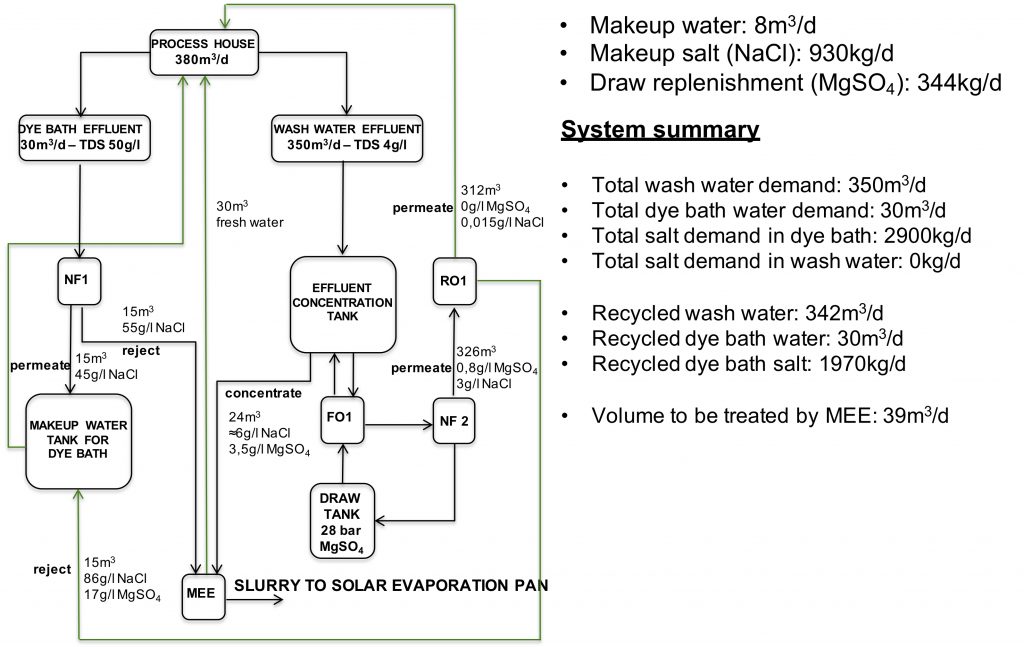

Improved resource recovery from textile dyeing wastewater when including an NF-type FO membrane

Based on preliminary calculations, including an NF-type FO membrane sub-system – to the conventional NF/RO/MEE ZLD set-up outlined above – significantly increases overall resource recovery:

- 16% increase in water recovery (from 321m3/d to 372m3/d)

- 71% increase in salt recovery (from 1152kg/d to 1970kg/d)

In case you’re interested in the parameters considered for the membrane sub-systems…

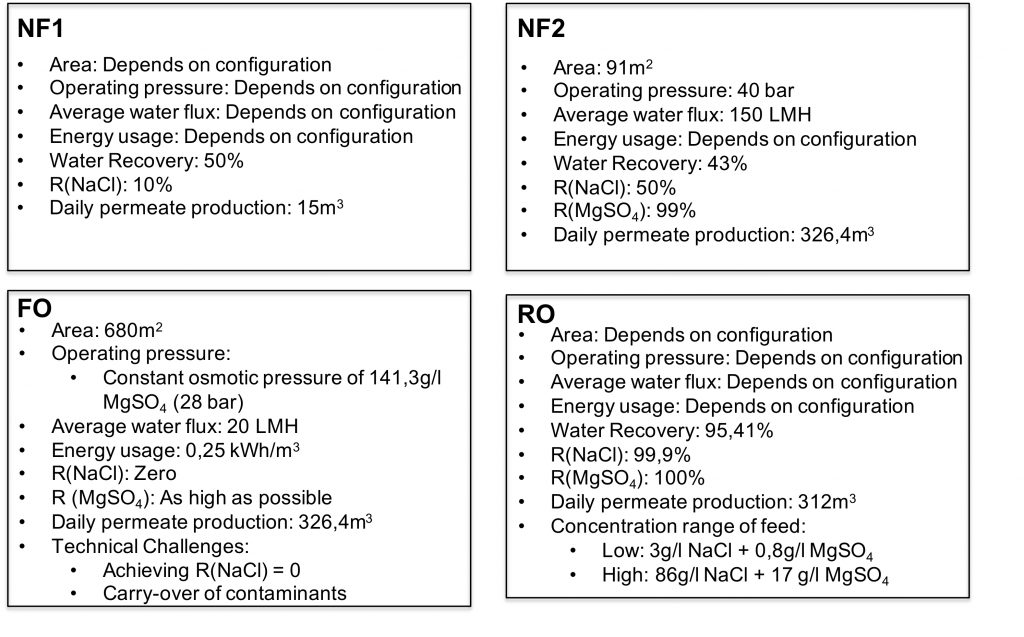

The overview below summarizes the main parameters of the membrane sub-systems in the proposed FO/NF/RO/MEE set-up outlined above. In addition, the overview touches on the main technical challenges relating to the NF-type FO sub-system, namely:

- Achieving a close-to-zero rejection for NaCl while maintaining a high rejection to divalent salts such as MgSO4.

- Dealing with carry-over contaminants (e.g. BOD, COD, etc) in the forward osmosis draw loop. Over time, trace contaminants from the feed stream will build up in the draw loop, which – if not dealt with – will lead to fouling of both the FO and NF sub-systems.

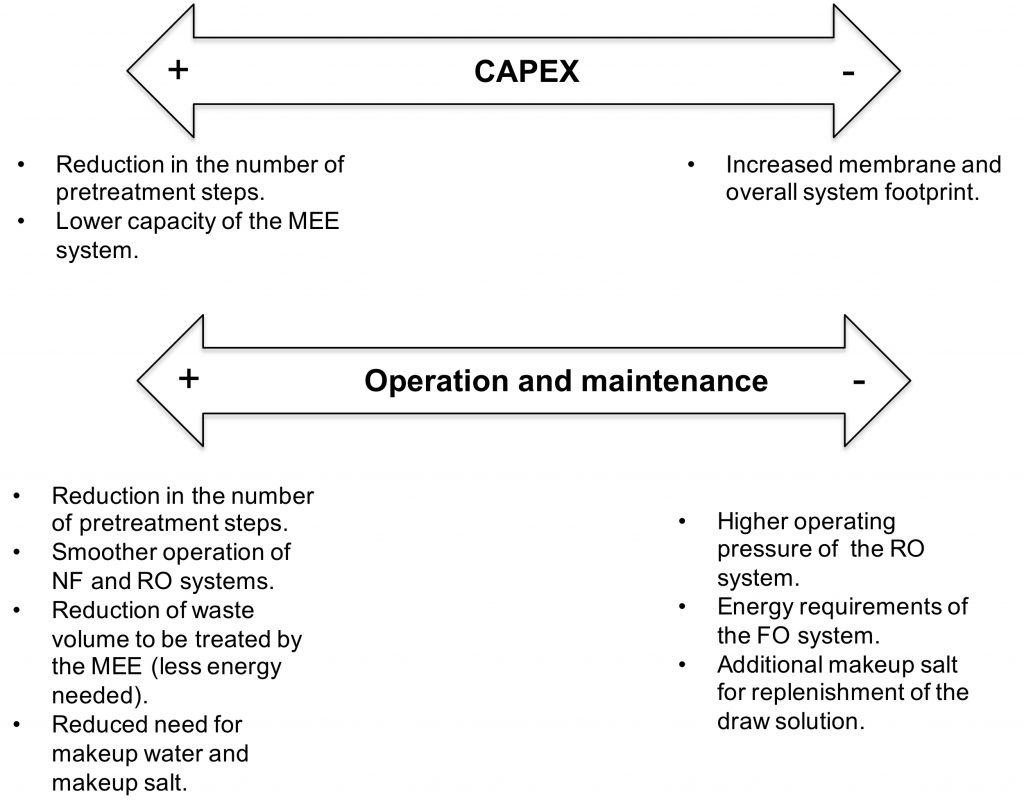

Trade-off summary and “back-of-the-envelope” business case comparison when adding an NF-type FO sub-system

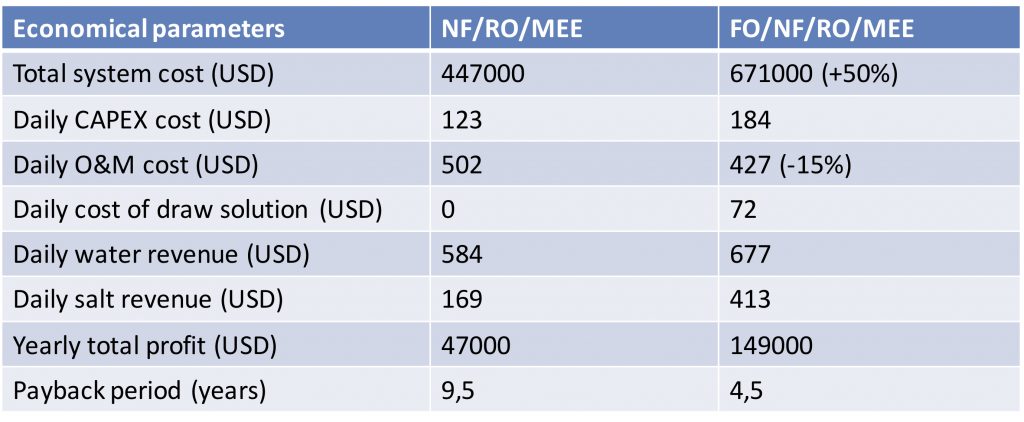

In conclusion, the trade-off summary and “back-of-the-envelope” business case comparison, shown below, demonstrate the operational & economical benefits of including an NF-type FO sub-system in the treatment of wastewater from textile dyeing processes.

In fact, the “back-of-the-envelope” business case comparison (based again on Vishnu et. al. 2008) indicates a 50% improvement in ROI, which is primarily due to the value of increased salt recovery.

Parting thoughts

It would seem, that Forward osmosis membranes capable of extracting both water and selected solutes, hold potential for improving the commercial relevance of FO-based water treatment.

Next step: commercially available NF-type FO membrane modules?