- Forward osmosis draw solutions and draw solution recovery methods - January 4, 2018

Draw solutions and draw solution recovery methods are key to unlocking the business potential of forward osmosis

I am a membrane enthusiast working in Aquaporin for the past 3 years. Previously, I had spent some time in the R&D labs & production line developing novel membrane products for the market.

In my current Business Development role, I aim to step out of our laboratories to share the fine art of FO with the world and explore ways to use FO to help solve their challenging problems all for the goal for full FO commercialization.

Lately, I’ve been working on putting together an overview of my take on the current status of forward osmosis draw solutions and draw solution recovery methods.

If the article below raises your interest in FO technologies, please do not hesitate to contact me at siewyewee@gmail.com for more information.

Why choose FO in the first place?

System integrators accustomed to using pressure-driven RO processes usually approach us with these 2 burning questions:

- Why should we use FO instead of RO?

- Why is there a need for draw solution regeneration in FO?

The answer to the first question is simple. FO does not require a hydraulic pressure as a driving force. Because of that, FO membrane processes generally have a lower fouling propensity and require less energy to operate.

The second question is much more complex and warrants a more detailed explanation. This article will provide some practical tips and tricks to select the right draw solute for your FO system as well as a rough guideline on how to approach draw solution recovery.

Why do FO processes require a draw solution recovery system?

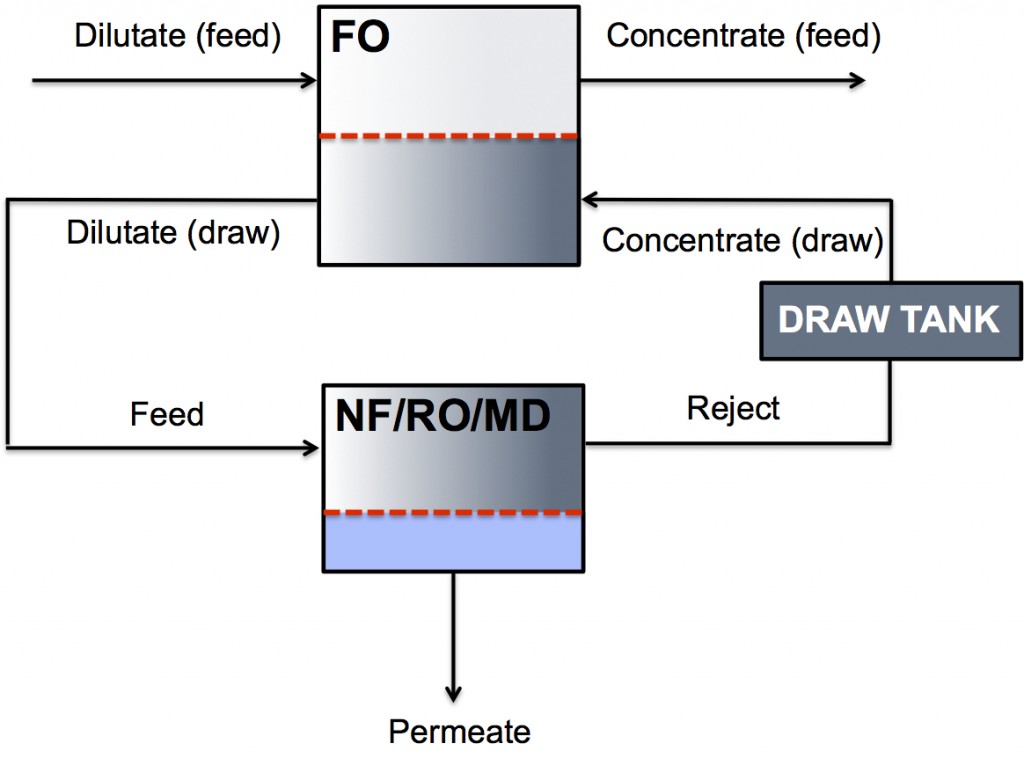

In an ideal scenario, FO can operate as a stand-alone system where water moves across the membrane spontaneously, concentrating the feed and diluting the draw in the process. One such application involves the dilution of SWRO reject for discharge into the seas by drawing water from a wastewater feed. Unfortunately for most FO applications, we do not have the luxury of such an elegant solution.

For the majority of FO applications, a FO-Draw Recovery hybrid system is necessary for meaningful and practical industrial operations, simply because of 3 inherent process conditions:

- Absence of a high osmotic pressure partner ‘free’ stream to be diluted (Stand-alone FO is not possible)

- A constant driving force (osmotic pressure difference) needed to maintain and drive the FO process

- Liberation of clean water trapped in the solute solution for recycling and reuse

Draw solute selection

Before we proceed, it is important to take a step back to understand what constitutes a good draw solution. The choice of draw solute will directly affect which draw solution recovery method to apply. As the driving force of the FO process, the draw solute must exhibit high solubility in water, high osmotic pressure and high diffusion coefficient (low molecular weight), governed by the theories proposed by Van’t Hoff. For example, NaCl is a better draw solute than sucrose due to a higher diffusion coefficient.

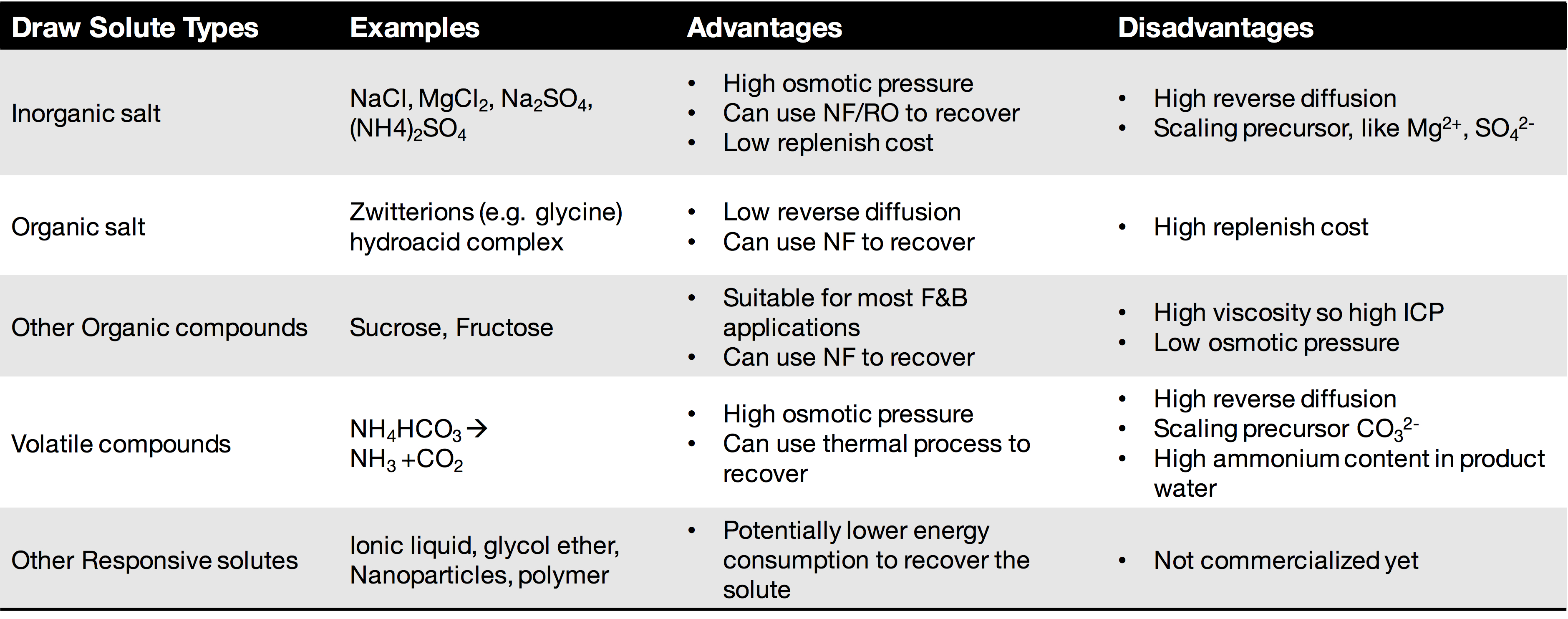

The types of commonly available draw solutes and its’ corresponding pros and cons are summarized in the table below.

Typically, inorganic salts such as NaCl are chosen as the draw solute as it is readily available, cheap and provides the necessary osmotic pressure in the draw solution for a broad range of applications. A suitable solute for an intended FO application can be selected based a few simple guidelines.

Ideally, the draw solute should be benign to the FO membrane and does not have any solute-membrane interactions as it will lead to scaling complications on the membrane substrate. This will unnecessarily elevate the membrane cleaning related cost.

Next, the reverse solute flux of the solute should be kept to a minimum. This is especially important in applications involving valuables up concentration where the final concentrated product needs to be pure. In the case where a reverse solute flux is inevitable, a compatible solute should be selected as a draw solute whenever possible. For example, sucrose is an excellent draw solution for fruit juice up-concentration since the reverse solute flux does not cause any major impact on the value stream or in some cases value add to the stream. Loss solute from the draw needs to be replaced with solute top up on the draw side. A high reverse solute flux into the feed stream will further incur the overall operating cost.

Lastly, the viscosity of the draw solution at high concentration values needs to be low to allow ease of flow on the draw side. High viscosity operations are tricky as it clogs the membrane and causes pressure to build up within the system.

How do we choose the right draw solution recovery method?

At its’ core, draw solution recovery is essentially a brine solution treatment problem. The good news is that there are already many mature solutions available in the market.

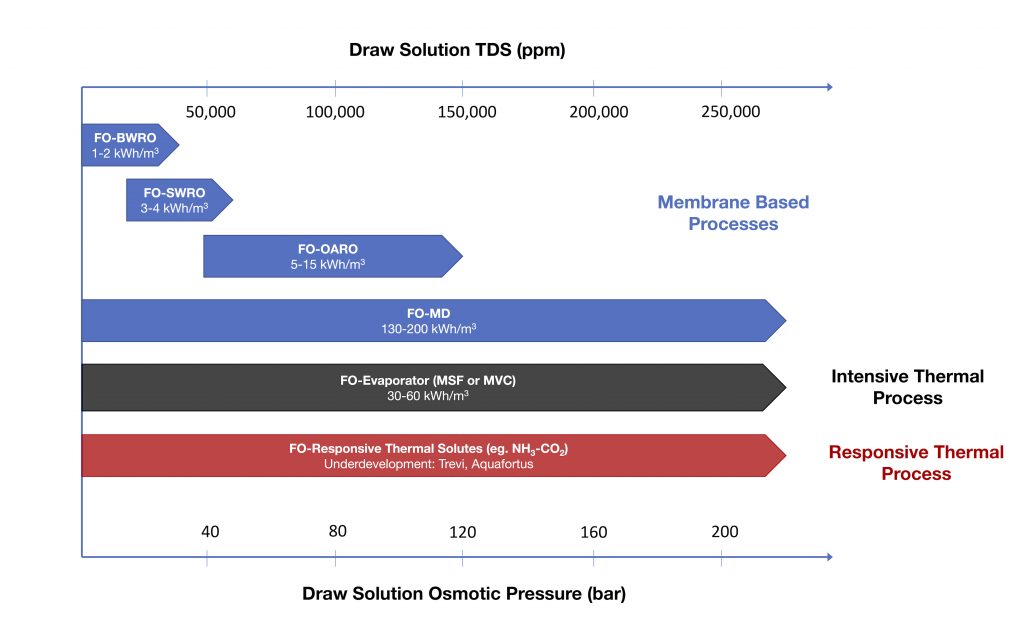

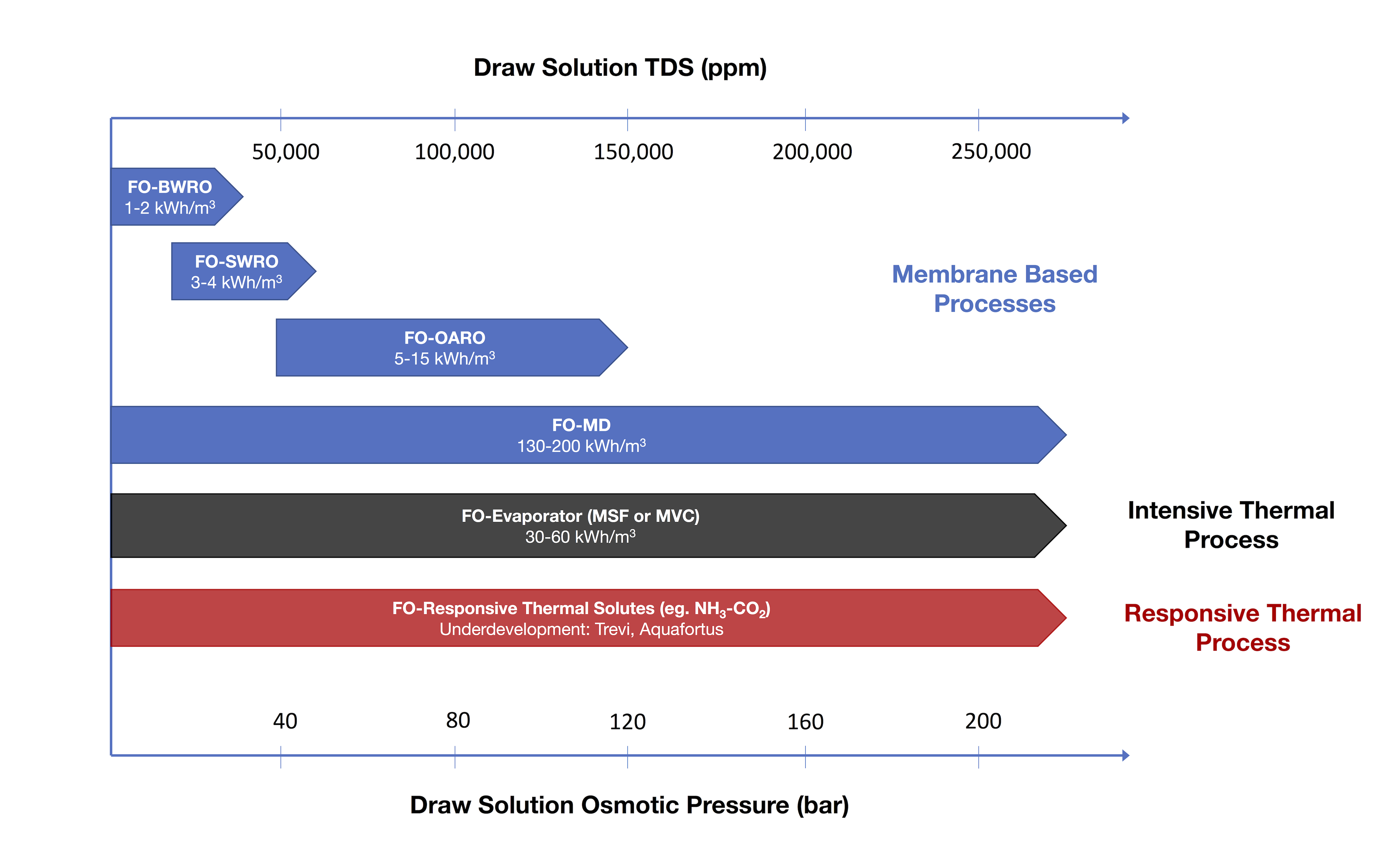

The draw recovery options available for pairing with FO can be broadly classified into either evaporation, membrane-based and responsive thermal draw solutes. The draw recovery methods and its’ corresponding range of TDS concentration or osmotic pressure are summarized in the figure above.

Thermal Processes

Multi Stage Flash Distillation (MSF) and Muliti-Vapor compression (MVC) are thermal evaporation based technology that can recover the draw solution at a wide TDS range at the expense of high energy consumption from 30-60 kWh/m3.

Membrane Based Processes

Membrane based processes for brine treatment range include nanofiltration (NF), brackish water reverse osmosis (BWRO), seawater reverse osmosis (SWRO), osmotically assisted reverse osmosis (OARO), disk tube reverse osmosis (DTRO) and membrane distillation (MD). NF, BWRO & SWRO are hydraulic pressure driven processes that require no further introduction. They are well established desalting technologies used for various industrial applications.

Osmotically Assisted Reverse Osmosis (OARO) & Disk Tube Reverse Osmosis (DTRO)

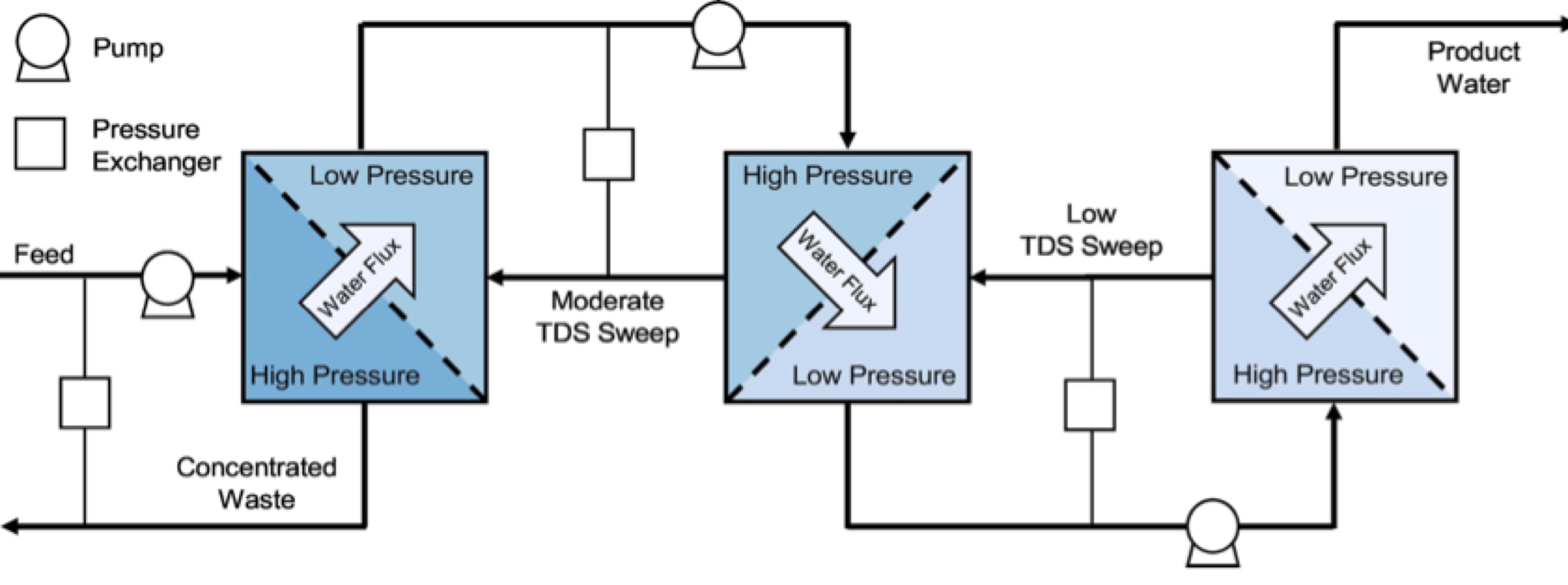

OARO is a multi-stage RO with a twist. The permeate side is exposed to a counter current sweeping salt solution (similar to a draw solution stream in FO). This sweep solution is fed into the next stage OARO until the final stage where a simple low pressure RO would suffice for permeate generation. With this combination of RO stages, OARO can treat draw solutions up to 150,000 ppm. Conventionally used for landfill leachate treatment, DTRO can handle up to 100 bar of osmotic pressure in the brine solution owing to its unique module design.

Membrane Distillation (MD)

MD is a thermally driven membrane process where vapor passes through its’ hydrophobic membrane pores.MD becomes an attractive option for draw recovery regeneration only when low quality waste heat is readily available in the plant due to inherent high-energy requirements.

Responsive Thermal Processes

Additionally, there are special responsive draw solutes such as ammonium bicarbonate draw system which can be easily regenerated into ammonia and carbon dioxide under an external thermal stimulus. These are elegant systems but faces challenges with high reverse solute flux and scaling issues which limits the scope of practical application.

Practical draw solution design considerations

After considering the possible draw solution recovery methods based on TDS and energy requirements in the previous section, I would like to leave you with 2 more practical design considerations:

Limiting osmotic pressure difference

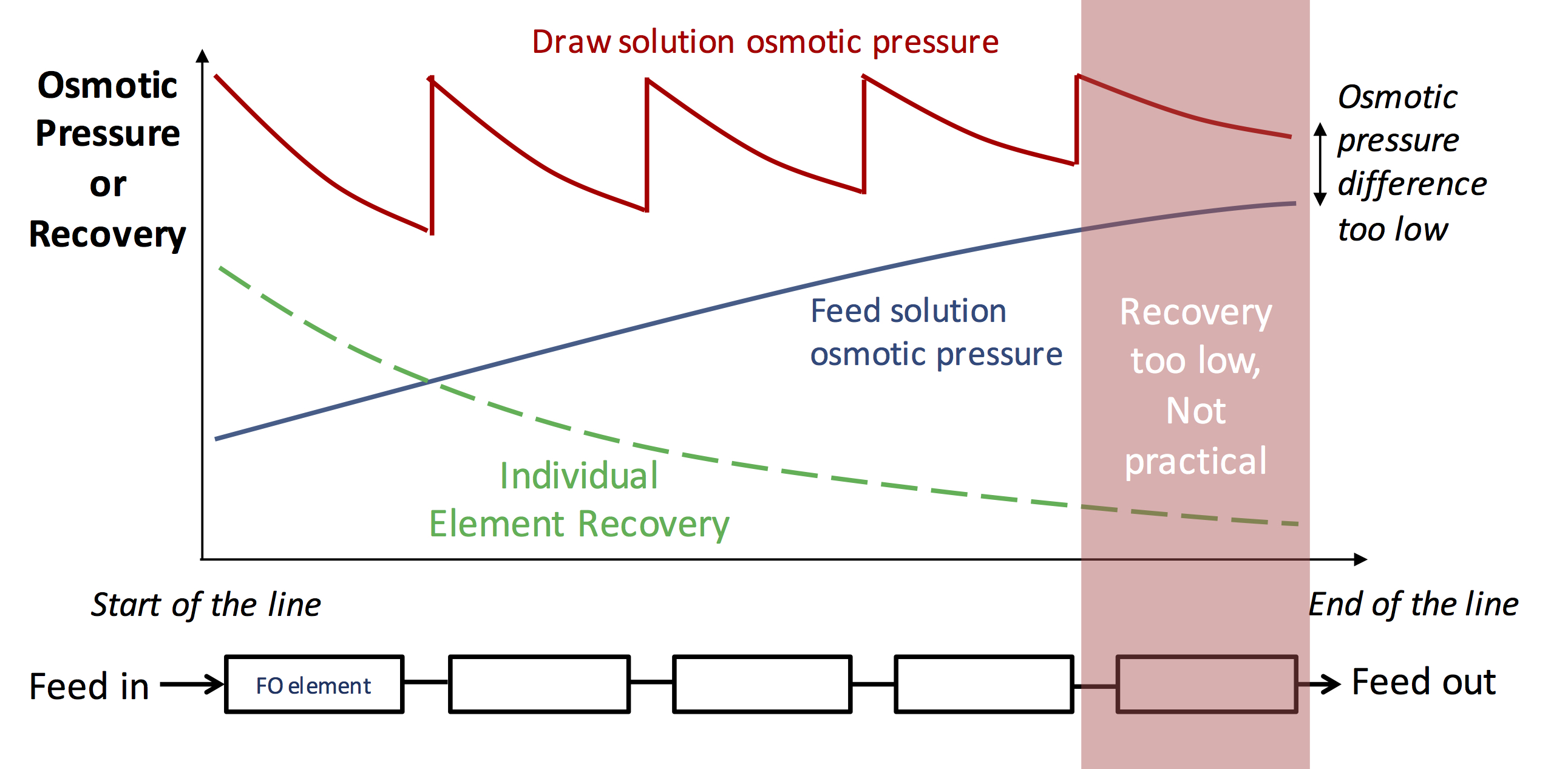

FO is a process driven by the laws of the second law of thermodynamics and must be obeyed. Water recovery in the FO process becomes low when the osmotic pressure difference between feed and draw becomes too small.

As a rule of thumb, the limiting apparent osmotic pressure* difference between feed and draw should be maintained at approximately 10-15 bar to attain appreciable flux as illustrated in the figure above. (this may vary based on the application and type draw solute and FO membrane used)

*Only apparent osmotic pressure is measurable. Real osmotic pressure difference may be lower due to internal concentration polarization

Trading off water recovery and draw recovery cost

A FO process with a high TDS draw solution will undoubtedly achieve a higher flux and water recovery. However, the corresponding draw recovery process will be costly as more energy intensive methods must be applied to concentrate the draw solution. For practical applications, we need to strike a balance between water recovery and cost incurred from the draw recovery process.

Conclusion

There is no one size fit all solution for choosing the most suitable draw solution and recovery method. When concentrating valuables or dewatering difficult to treat wastewater, FO represents a very promising solution. Depending on the operating conditions and where the draw solution is on the TDS equivalent range, suitable and mature draw regeneration options exist. Therefore, for the right applications, FO-hybrid systems offer significant value and can be cost competitive with conventional solutions.