A general introduction to forward osmosis applications

We realize that navigating any portal can be challenging at times. To make life easier for you – our readers – we have therefore decided to summarize all our forward osmosis application related knowledge on a single page with the aim of creating a more accessible entry point to the ForwardOsmosisTech portal. We hope we have succeeded in doing so below. As always, send us a mail at forwardosmosistechportal@gmail.com if you have suggestions for improvements or simply have something on your mind you want to share with us.

Concentration, dilution, water production, and energy production

As the title suggests there are essentially 4 ways for forward osmosis systems to provide value in end user applications:

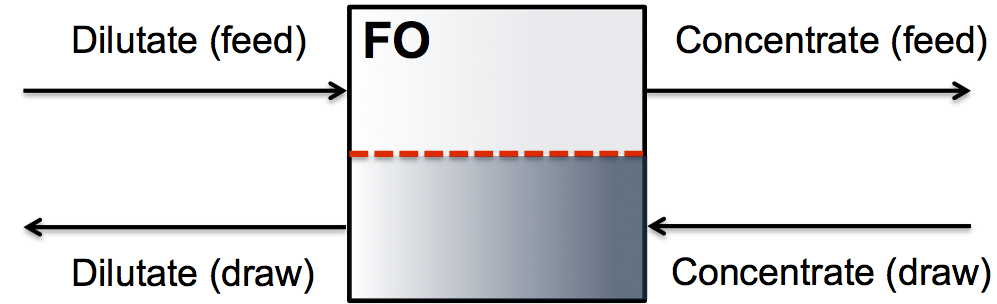

- Concentration, where water is extracted by forward osmosis processes from specific feed streams. Continuous extraction of clean water from said feed solutions will result in volume reduction, which in effect concentrates solutes and any other components. This process is also known as dewatering.

- Dilution (indirect water production), where water is extracted from feed streams by forward osmosis processes into a given draw solution. Continuous extraction of clean water into the draw solution will result in volume increase, which in effect dilutes solutes and any other components. Dilution can be seen as an indirect way of producing water.

- Direct water production, where the clean water extracted from feed streams into draw solutions is separated from the draw solutes by means of complementary separation processes (e.g. reverse osmosis, nanofiltration, ultrafiltration, membrane distillation, thermal separation etc.).

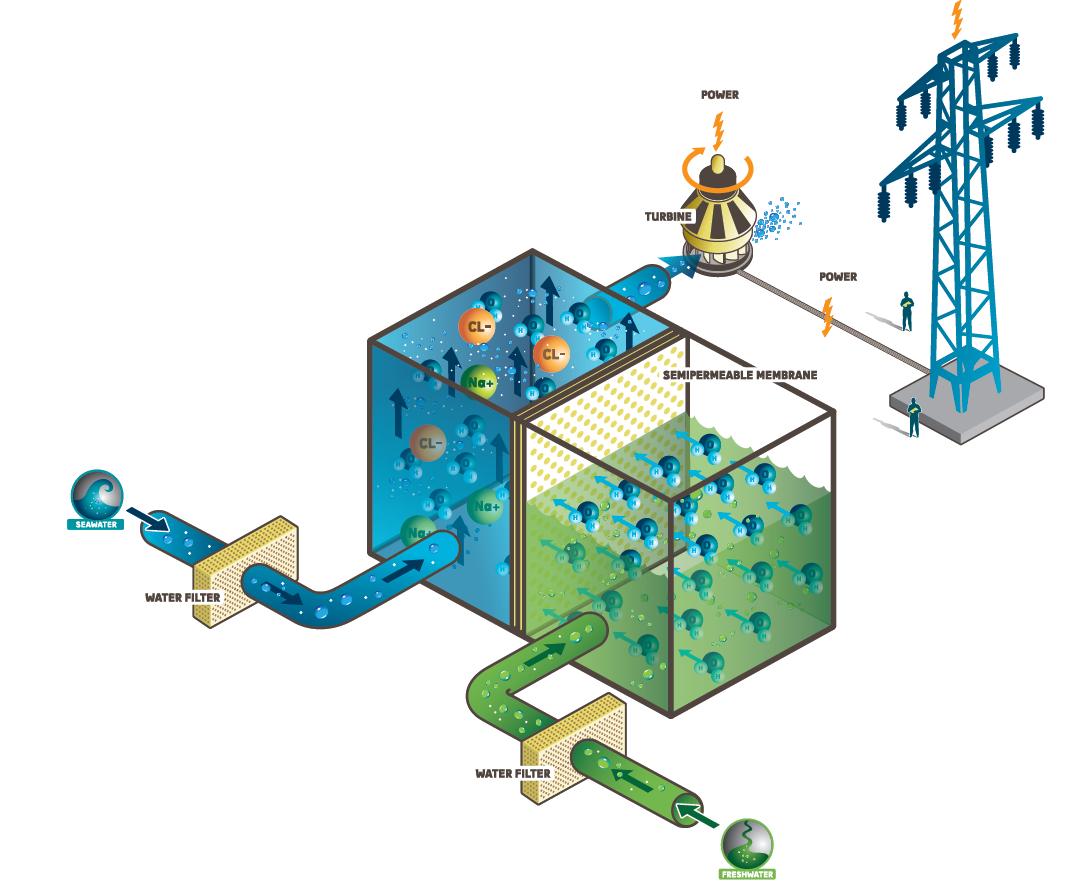

- Energy production, where the clean water extracted from feed streams into draw solutions is used to generate hydraulic pressure on the draw side, which in turn can be used to generate electrical energy via turbines. This process is known as pressure retarded osmosis.

The table below summarizes a few examples of real-life applications, where the 4 value generators described above are put to use. Notice that some applications utilize more than one value generator and thus provide value to end users on several levels.

| Application | Utilized value generator |

Industrial wastewater treatment – example 1 |

|

Industrial wastewater treatment – example 2

|

|

Industrial wastewater treatment – example 3One of the best application areas for forward osmosis systems can be found within the field of industrial process optimization. Imagine a factory/plant with two separate aqueous streams: one needs to be concentrated and another needs to be diluted. Traditionally these streams are treated separately but a forward osmosis system is able to utilize the osmotic pressure in the concentrated stream to extract water in a low energy fashion from the diluted stream. Thus, forward osmosis systems offer the possibility to replace two costly treatment processes with a single-step, low energy process. In our article about stand-alone forward osmosis systems we give an example of how forward osmosis technologies can be used for industrial process optimization in traditional RO-based desalination plants. |

|

Osmotic power generation – example 1

|

|

Osmotic power generation – example 2

|

|